Microelectronics/3C electronics industry: such as high -definition camera module, camera soft board connection point, precision acoustic control device, sensor, VCM module, and other precision tiny components welded.

Military electronics manufacturing industry: welding of aerospace high precision electronics.

Others: Welding of high precision components and high precision electrons such as wafer, optoelectronics, MEMS, sensor production, BGA, HDD (HGA, HSA).

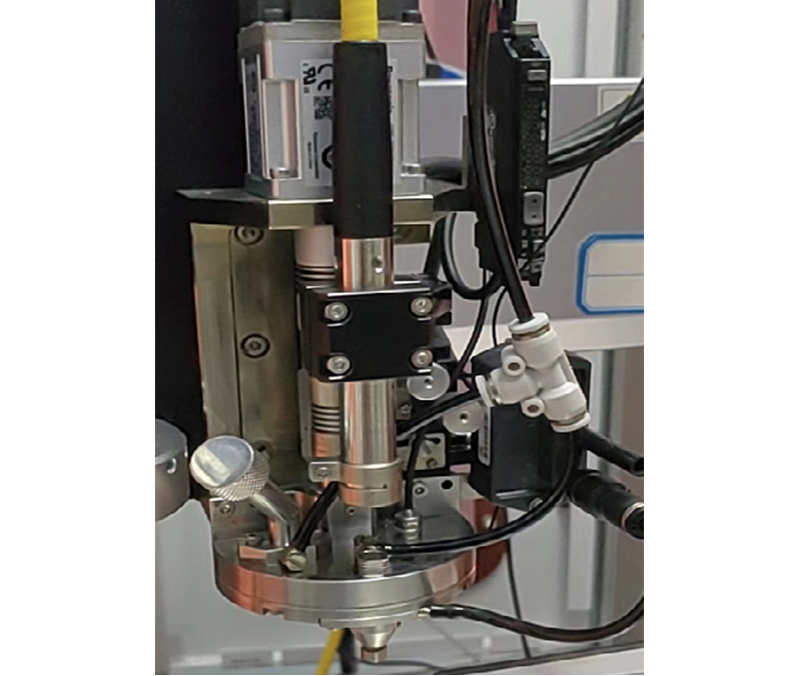

Equipment features

• The process of heating and dripping is fast, which can be completed within 0.2s, and the heat affects the area small;

• Complete the tin ball melting in the welding mouth without splashing;

• No need to help welded, no pollution, to ensure the life of the electronic device to the greatest extent;

• Non -contact welding, no static electricity;

• The smallest diameter of the tin ball is 0.05mm, which is in line with the development trend of integration and precision;

• The welding of different solder joints can be completed through the selection of tin ball size;

• With the CCD positioning system, it is suitable for the large quantities of the assembly line.

Equipment parameters

| project | Specification |

| gas | High purity nitrogen |

| UPH | 7200 |

| Yield | ≥99.5% |