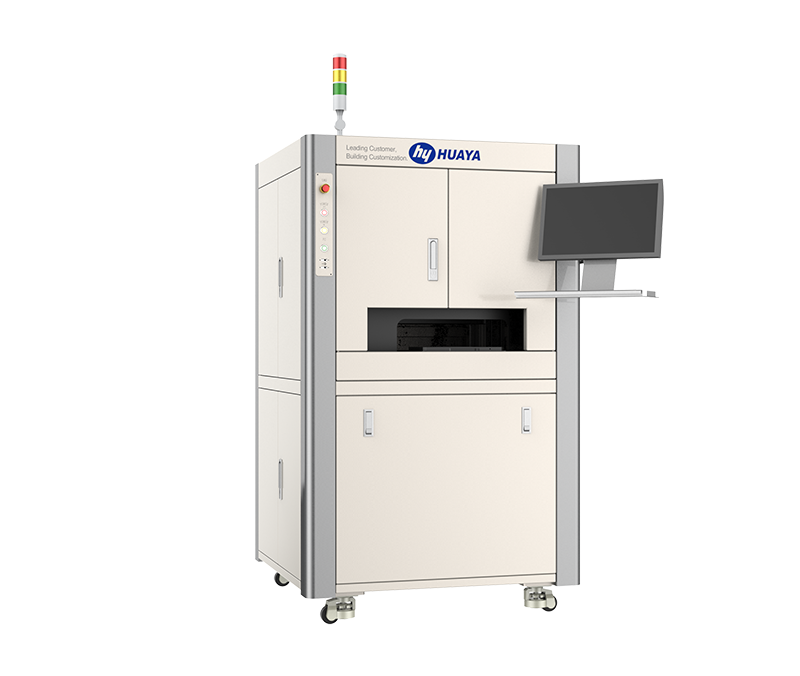

Basic parameters of the device

• Size: 1000*1000*1670, mm

• Power: 1KW

Equipment Advantages

• High laser test;

• Equipped with high -precision electronic scales;

• Have visual positioning and point -to -point effect detection;

• Configure MES function;

• Support customer customization.

Main Functions

| The main function | describe |

| sport control | 4/8 axis servo control |

| visual function | Visual positioning and Mark correction, visual glue width measurement, dispensing NG detection |

| Weighing | High-precision weighing, weighing compensation, optional glue processing mode for processing |

| Laser Altimeter | Glue height measurement, global or sub-block height measurement compensation, high-precision height measurement for fixed-height dispensing |

| Needle calibration | Can be combined with through-beam sensor, vision, tool setter, etc. for one-key calibration, needle change calibration |

| Glue circuit program generation | Needle teaching, visual teaching, DXF file import |

| Glue making tools | Points, lines, arcs, circles, rectangles, bows, loops, etc., support subroutines, arrays and other glue path production methods |

| Dispensing effect detection | Selected area training image template, can detect whether the product is abnormal before dispensing |

| Loading and unloading system | Docking with PLC or axis card-controlled loading and unloading system (customizable loading and unloading action process) |

| code scanning gun | Bar code reading, switch processing work orders according to the bar code |

| MES | Dispensing control system docking with MES system |

| Customized process selection | Non-standard dispensing process control function customization |